Kanban is a Japanese word that means “visual card”. Kanban is a system for organising workflow, task prioritisation and effective use of personnel and resources for just in time delivery (JIT). JIT sample analysis is enhanced by automation, efficient sample levelling and continuous operatioal flow.

1. Process visibility

In a Kanban system it is important to visualize the work flow. This may involve creating a Kanban board, dividing the work process in to smaller steps, each step is identified by a specific coloured card. The card contains the information about the process and the person responsible. The cards are placed on a workflow (Kanban) board outlining samples waiting for analysis, queued, work in progress (WIP), completion and release so that the process flow and progress is clearly visible.

2. Limited WIP (work in progress)

In the Kanban system, increasing the visibility of a process and task status makes it easy to identify backlogs, constraints, overburdened employees and bottlenecks. The system sets specific limits for how many items may be processed at any time. In this way tasks are completed just in time (JIT) to limit backlog.

3. Monitor lead time

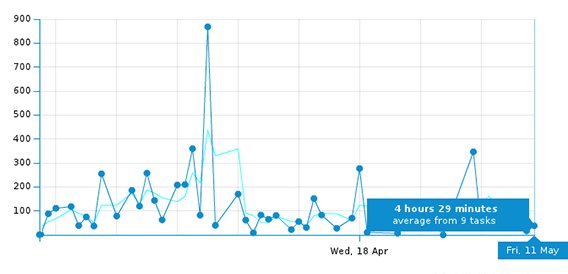

The Kanban system optimizes processes by predicting workflow and reducing the lead time - average amount of time it takes for a task to be processed from the specific start to the finish point. In laboratoty terms, this can relate to the amount of time it takes to process a batch from collection, sample analysis and data transfer. Kanban metrics can be used to analyze the time required to process samples to make improvements for an efficient continous flow operation.

4. Make Process and Policies Explicit

Processes need to be clearly defined, explicit and communicted effectively in order to be understood. Without clear ojectives and general consensus, people are less likely to engage in process improvement and and adopt changes.

5. Collaborative Improvement

The success of Kanban requires small incremental changes for continuous improvement and sustainment. Team engagement and a holistic approach to continuous improvment throughout the facility is essential.

Kanban Inventory

Managing inventory is an important aspect of minimising waste in laboratories and it complements the 5S initiative. A Kanban system may be used for inventory maintenance, particularly restocking. Other inventory examples where Kanban is apparent include colour indictors for different samples according to urgency or batch, a common practice in clinical labs.

Kanban Board

A Kanban board is an effective visual management tool that provides an excellent overview of a current work situation by making process flow, tasks and responsibilities clearly visible. It enables clear identification of backlogs, heavy workloads, overburdened resources and personnel. It is also an excellent way for employees to keep track of their own progress and work load management and it simplifies communication within a team to enhance productivity.

There are also numerous digital Kanban software programs which may be a good tool for integration with LIMS to enhance communication and collaborate analyses in real time.

|

| http://leankit.com/kanban |

No comments:

Post a Comment